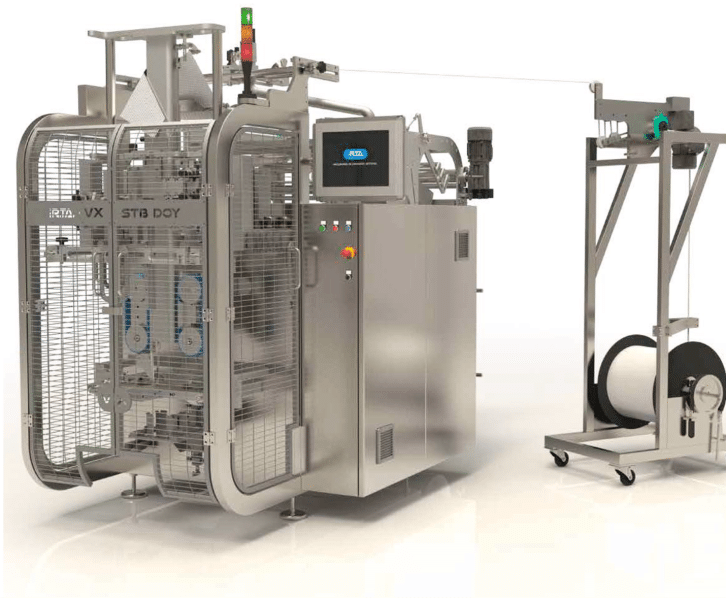

BPI Packaging Equipment Unveils 5-Bag IRTA VX STB Doy Machine

BPI Packaging Equipment is proud to announce our latest partnership with IRTA Group Packaging, a move that will bring cutting-edge versatility to packaging operations across North America and beyond. At the center of our collaboration is the IRTA VX STB Doy, a next-generation vertical multiformat unit engineered for speed, performance and flexibility, accommodating five distinct bag types.

If you’re seeking high-output equipment that easily handles multiple bag formats while maximizing floor space and minimizing energy use, this is the machine that will transform your line.

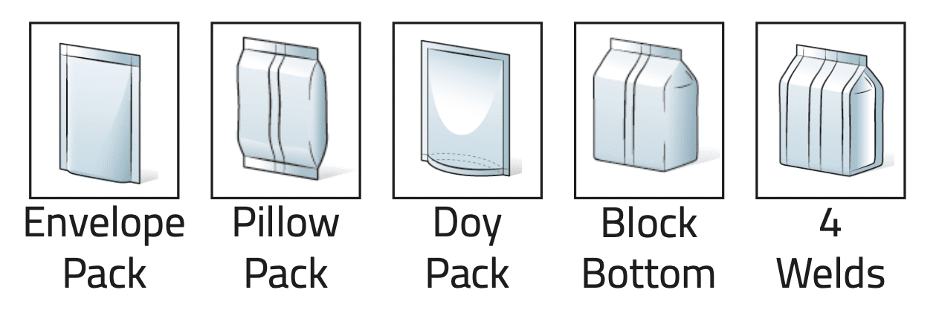

One Machine. Five Bag Formats. Endless Possibilities.

The IRTA VX STB Doy is a packaging powerhouse built with adaptability at its core. With the ability to handle five popular bag styles — envelope pack, pillow pack, doy pack, block bottom and 4-weld bags — this machine delivers the ultimate in flexibility without the need for multiple units or complicated changeovers.

For co-packers, snack producers and food manufacturers managing multiple SKUSs or product formats, the VX STB Doy is invaluable — saving time, reducing operational complexity and boosting uptime.

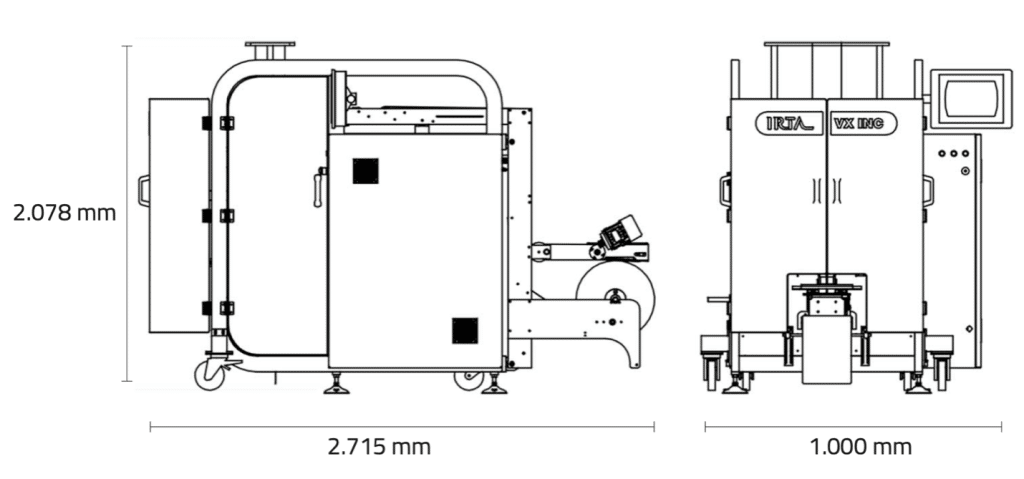

Compact, Fast & Built for ROI

With a design focused on speed and accuracy, the IRTA VX STB Doy boasts a compact footprint while achieving up to 110 cycles per minute. It’s an ideal fit for facilities with high output demands and limited space.

Key Features

- Adjustable bag widths from 50 mm to 350 mm

- Adjustable lengths from 40 mm to 500 mm

- Color touchscreen interface with multilingual support (Spanish, English, German, French)

- Rapid spool change system and motorized film unwinder for minimal downtime

- Stainless steel AISI 316 construction for durability and hygiene

- Ethernet and router included for easy integration and control

- IP 65 protection, for reliable operation even in challenging environments

Ideal for a Wide Range of Products

Perfect for packaging powders, snacks or granules, the VC STB Doy is specifically designed to meet the needs of a broad product spectrum, including:

- Nuts

- Dehydrated foods

- Cornflakes

- Sunflower seeds

- Coffee

- Candy

- Biscuits

- Snacks

- Breadsticks

Performance-Driven Engineering at Its Finest

From servo-driven mechanics and Becker vacuum pumps to Rockwell and Festo pneumatics, every element of the VX STB Doy is chosen for durability, performance and minimal maintenance.

Standard Features

- Film tension control with display feedback

- Temperature, welding time and pressure regulation

- End-of-film detection and alarm system

- Static film elimination and package vibration

- Optional add-ons such as zipper dispensers, label applicators, gas injection systems and easy-open blades

Invest in a Smarter Packaging Future

With its unbeatable quality-output-price ratio, the IRTA VX STB Doy machine offers one of the fastest returns on investment in the market today. Suited for packagers looking to upgrade their existing line or launch a new product that requires dynamic packaging capabilities, this unit delivers.

Ready to simplify your packaging process and boost ROI?

Contact BPI Packaging Equipment today to learn more about integrating the IRTA VX STB Doy into your production line.

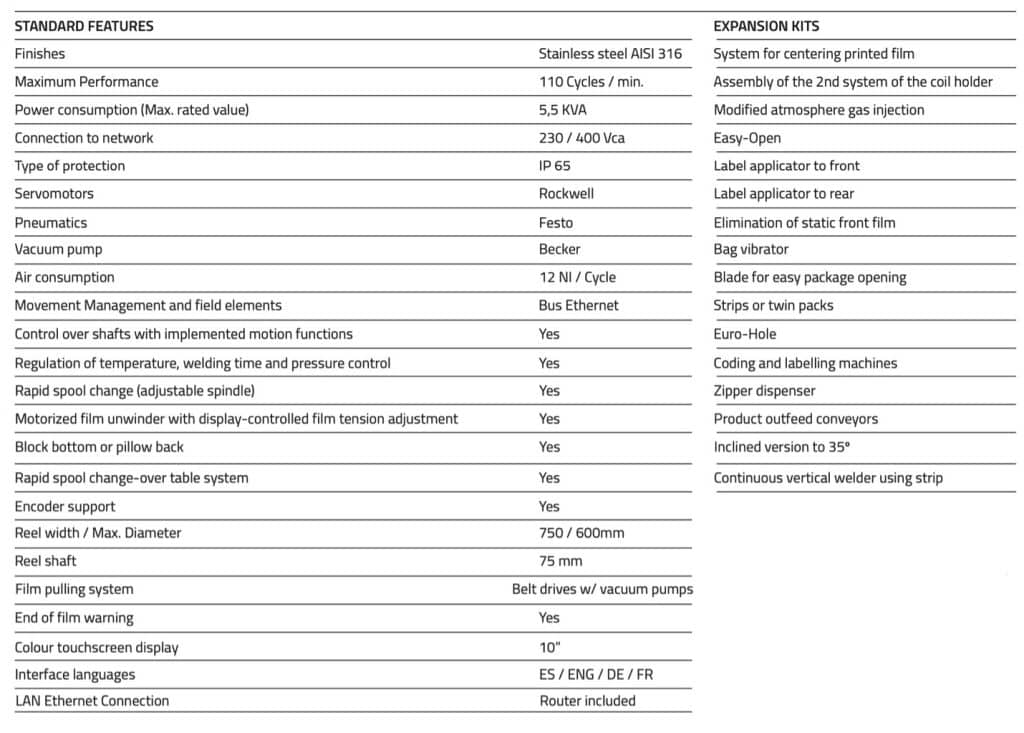

Standard Features & Expansion Kits