What to Consider Before Automating Your Packaging Process

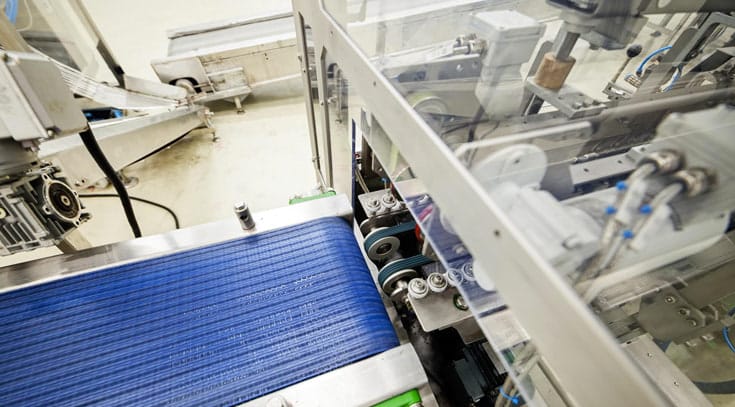

If you’re like most business owners, you’re always looking for ways to improve efficiency and increase profits. One of the best ways to do this is by automating your packaging processes. Automation can save you time and money — and it can help you produce a higher-quality product.

In this blog post, we will discuss the benefits of automation and how a business can get started. We’ll also provide some tips on choosing the right equipment for your needs.

Weigh the Benefits of Automation

There are several benefits to automating your packaging process. First, it can save you a lot of time. Manual processes are often slow and error-prone. Automation can help you get the job done faster and with fewer mistakes.

Second, automation can improve the quality of your product. When machines are doing the work, they can often do it more accurately and consistently than humans. This can lead to fewer defects and a higher overall-quality product.

Finally, automation can save you money. When done correctly, automation can help you reduce labor costs, material costs and waste.

Align with a Consultant

Before automating a packaging process, it’s critical to align with a consultant who understands the intricacies of the machinery and the packaging line as a whole. By doing so, you can ensure the machinery is configured and operated in the most efficient manner possible, thus maximizing throughput and minimizing downtime.

When a business is ready to take its next step toward automation, decision makers often hold a one-size-fits-all misconception toward packaging machinery. A consultant from BPI can help you choose the right machinery for your specific application, taking into account factors such as product size and shape, packaging requirements and production volume. This can save you time and money in the long run by ensuring you don’t purchase machines that are not suited for your needs.

Finally, a consultant can help you design an effective production line that takes into account the limitations of your current facility and the constraints of your workforce. This will help to ensure that your new automated process runs smoothly from Day 1.

Consider Variables & Factors

When looking to invest in automated packaging processes, there are a few important variables and factors a business should consider.

One of the most important considerations is the type of product being packaged. Different products have different shapes, sizes and weights, so it’s important to select the right packaging equipment to accommodate those variations. BPI offers a variety of baggers that can accommodate a wide range of products, from cheese and coffee to raw poultry and fresh vegetables.

Additionally, businesses should take into account the speed and volume at which they need to package products in order to determine what type of equipment is most appropriate.

The amount of packaging flexibility required is also something to keep in mind. Some businesses may only need a machine that can package one type of product, while others may need machines that can accommodate multiple products or sizes.

Another key consideration is the packaging material. Some types of packaging materials are easier to work with than others, so it’s important to choose a material that is compatible with the bagging equipment. Businesses should make sure they have enough of the desired packaging material on hand to meet their production needs.

Finally, businesses should assess their budget and decide how much money they’re willing to spend on automated packaging processes. While not all equipment is prohibitively expensive, certain types of bagging equipment can be costly. It’s important to weigh the costs and benefits of each option before making a decision.

BPI brings smart and profitable solutions to our clients with innovative technology, state-of-the-art automatic packaging equipment, on-site service and a full parts and fabrication department. Contact us today for your next step toward efficiency and growth!