A Smarter Way to Package with BPI’s Premade Pouch Machine

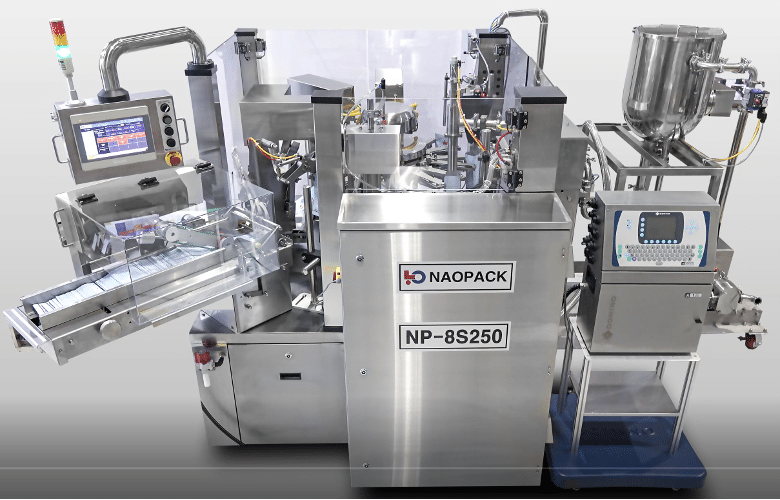

For businesses packaging products such as pool chemicals, powders or bulk goods, consistency and uptime are critical. The BPI OP-8S-410 Premade Pouch Machine delivers both, combining rugged construction with intuitive controls to simplify operations and maximize output.

This machine is built to handle stand-up zipper pouches with a wide range of sizes, making it a versatile tool for growing product lines.

Fast Changeovers

Switching between bag sizes takes less than 10 minutes, thanks to tool-free adjustments and an easy-to-use touch screen. Operators can adjust all eight grippers at once and manage bag magazine changes with quick-release handles.

Dependable Sealing

A dual-station sealing system (one for sealing, one for pressing), makes certain every pouch leaves the line with a strong, uniform seal. This reduces leakers, keeps products fresh and maintains a clean, professional finish.

Designed for Easy Maintenance

The automatic central lubrication system and washdown-ready structure (IP65 standard, IP66 optional) simplify upkeep while extending the life of the equipment. With stainless steel 304 and 316 contact parts, durability is built in.

Performance You Can Rely On

Output: 7–20 bags per minute, depending on product and pouch size

Filling Volume: 4–28 pounds

Bag Range: Width 220–410mm, Length 250–520mm

Construction: Heavy-duty welded steel frame with stainless steel product contact parts

Control: Omron PLC with Easy View touch screen, backed by alarms and troubleshooting guides for quick issue resolution

Safety and Quality at Every Step

The OP-8S-410 comes equipped with intelligent safety features such as:

- No bag, no fill, no seal

- Alarms for temperature fluctuations, motor overload or incorrect gripper width

- Secure start-up requiring input of a secret number

- Automatic stops for low air pressure or abnormal operating conditions

These safeguards protect your product, your operators and your investment.

Packaging Process

- Bag load: About 100~300 bags (standup pouch) can be stored on the bag magazine manually, and then bags are fed automatically to the gripper on the turret, with a date code option.

- Mechanical zipper opener

- Top and bottom open

- Product fill / dust

- Settle

- Dust

- Seal / air reduce

- Cool & Discharge / weight check & weight feedback to the auger filler(option)

Optional Upgrades for Maximum Efficiency

Every machine includes essentials like a pouch opening detector, dust collection funnel, discharge conveyor and mechanical zipper opener. Optional upgrades, such as epoxy-coated parts (included in base price) and an IP66 washdown package ($75,000), provide even more durability for demanding environments.

Why Choose BPI Packaging Equipment?

Beyond the machine, BPI provides the expertise, service and parts support you need to keep your lines running. From installation to operator training, our team is committed to making sure your investment performs from Day 1.

Ready to bring speed and consistency to your packaging line? The OP-8S-410 Premade Pouch Machine is available now.