BPI Equipment Unveils New Bottle Unscrambler, Sprayer Inserting System & Bottling System

A leader in automated packaging, BPI Packaging Equipment introduces our advanced bottle handling and filling stations, the newest additions to our suite of automated packaging solutions.

From organizing bottles and placing sprayer heads to filling liquid products, this combination of machines is designed to boost productivity and maintain precision across various bottle packaging stages. Here, we’ll take a closer look at three of our key machines — the Bottling Unscrambler, Sprayer Inserting System and Bottle Filling System — and explore how they enhance efficiency and accuracy of packaging lines.

Simplifying Bottle Placement with BPI’s Bottle Unscrambler

The Bottle Unscrambler is a versatile machine engineered to handle bottles of multiple sizes, organizing them into a single line on a conveyor belt. This system minimizes labor by automating the alignment and placement of bottles, making it ideal for large-scale bottle operations.

Key Features & Advantages

Speed & Flexibility

The Bottle Unscrambler can process up to 60 bottles per minute, with speeds adjustable depending on the bottle size. Its separator head accommodates bottles from 1 oz. to 32 oz., adapting to various shapes and sizes.

Technical Precision

Equipped with sensors for auto bottle alignment, the machine prevents misalignment and potential rejects, thus enhancing production efficiency.

User-Friendly Operation

The unscrambler’s design is tailored for easy adjustment and operation, making it accessible for new operators and reducing downtime.

Benefits of the Bottle Unscrambler

Labor Cost Savings

By automating bottle placement, labor needs are reduced, which translates to lower operational costs in the long run.

Consistency

The machine maintains consistent speeds for high output, creating a smooth and predictable flow of bottles to subsequent stages in the packaging process.

Broad Compatibility

Easily integrated with different bottle systems, our unscrambler can handle a wide variety of bottle shapes and materials such as glass, plastic, aluminum and more, making it suitable for several industries.

With options such as additional wheel sizes, conveyors and custom design features, BPI’s Bottle Unscrambler is fully adaptable to your specific production needs.

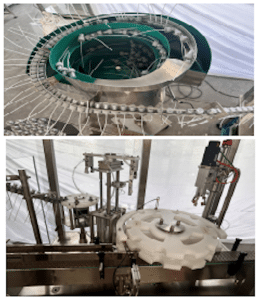

Sprayer Inserting System

Our Sprayer Inserting System is designed for the precise placement of sprayer heads, ideal for products requiring spray functionality, such as cleaning supplies, sanitizers and personal care products. This machine handles high speeds and various container shapes, ensuring each bottle receives the correct cap or spray head.

Key Features & Advantages

With speeds ranging from 1 to 320 bottles per minute, this system is built for high-capacity production lines.

Versatile Sprayer Handling

The Sprayer Inserting System can place different types of sprayer heads, including those for liquid, foaming and soft cream products.

Precision Application

Equipped with torque tightening for caps, the system consistent and secure placement of sprayers, reducing the risk of leaks or misalignment.

Benefits of the Sprayer Inserting System

Reduced Manual Labor

Automating sprayer head application speeds up the production process and reduces the potential of human error.

Accurate Placement

The system’s bowl feeders and cap applicators are custom designed to match specific sprayer types, providing reliable and accurate placement with minimal maintenance.

Customization Options

With additional features like custom torque tighteners and alignment wheels, the machine can be adapted for unique production needs.

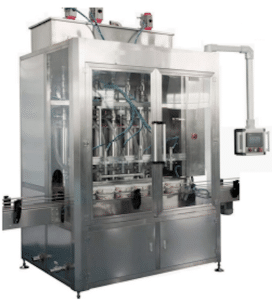

Bottle Filling System

BPI Equipment’s Bottle Filling System is a versatile machine that handles everything from small, 1-oz. containers to large, 5-gallon bottles, making is suitable for a wide range of operations, including food and beverage, pharmaceuticals and personal care.

Key Features & Advantages

Adjustable Filling Heads

The Bottle Filling System offers 1- to 12-head filling options, allowing flexibility in output. With a maximum speed of 720 bottles per minute, it’s designed for high-volume production.

Precision Filling Technology

Equipped with servo or pneumatic filling heads, this system delivers accurate dosing and minimal waste, both of which are crucial for our customers.

User-Friendly Interface

Operators can easily control the system via a large HMI screen, simplifying the process of adjusting filling specifications to match various bottle types and liquid viscosities.

Benefits of the Bottle Filling System

Enhanced Efficiency

By reducing overfills and spills, the filling system not only conserves product but also reduces cleanup time and product waste.

Flexible Product Handling

From liquid foaming to semi-soft creams, the system can handle a wide variety of product consistencies to match your industry needs.

Customizable Options

Options such as Ethernet remote diagnostics, in-feed and exit conveyors and gas flush systems make it possible to tailor the machine to specific production requirements.

Our Bottle Filling System is a rugged solution for high-speed liquid filling, designed to easily integrate into complex production lines and deliver reliable results with minimum maintenance.

Why Choose BPI Equipment?

BPI Equipment is committed to improving the packaging process, with a suite of machines engineered with the latest technology to minimize labor, increase speed and enhance precision at every stage. With a focus on reliability and user-friendly operation, we empower businesses to meet the demands of high-capacity production with ease.

Contact BPI Equipment today to learn more about our comprehensive line of automated solutions!