Protect Consumers and Your Business with Inspection Equipment

Ensuring food safety is essential for all businesses involved in the food industry, from farms and processors to retailers and restaurants. After all, no one wants to end up with a batch of contaminated food products — or a lawsuit — on their hands. Not only are contaminants a health hazard but failure to catch them can be catastrophic for business.

That’s why it’s critical to have reliable inspection equipment in place during the packaging stage.

At BPI, we are proud to be a leading supplier of automated packaging solutions, offering a wide range of inspection machinery, including checkweighers, X-ray machines and metal detectors, that are vital for ensuring food safety during the packaging process. We have a deep understanding of the challenges faced by different industries, such as meat processing, pet foods and treats, candy and more, and we’re able to offer tailored solutions that meet the distinct needs of each.

Our state-of-the-art machines are designed to detect contaminants such as metal fragments, glass shards, bone fragments and plastic pieces that could potentially cause harm to consumers. In addition to protecting consumers, our inspection solutions can also help businesses avoid costly product recalls and preserve their reputation.

Checkweigher

The food industry is a vast and complex sector that requires stringent safety measures to ensure consumers receive the highest-quality products. Inspection equipment, such as an automated checkweigher, are integral components of any successful packaging process in order to guarantee accuracy and safety. Automated checkweighers offer a variety of benefits to companies as they eliminate human error and provide faster, more accurate results than manual methods.

An automated checkweigher is designed to quickly detect underweight or overweight packages, which helps manufacturers ensure product compliance with specifications set by local and international regulatory bodies. This is extremely important for food manufacturers as it allows them to reduce their risk of recalls due to inaccurate weight measurements or potential health risks associated with underweight products.

Furthermore, using an automated checkweigher can help improve overall product quality by allowing manufacturers to detect any issues such as broken seals or damaged packaging before it reaches the consumer. This can result in increased customer satisfaction as well as reduced costs associated with returns or refunds caused by improper packaging.

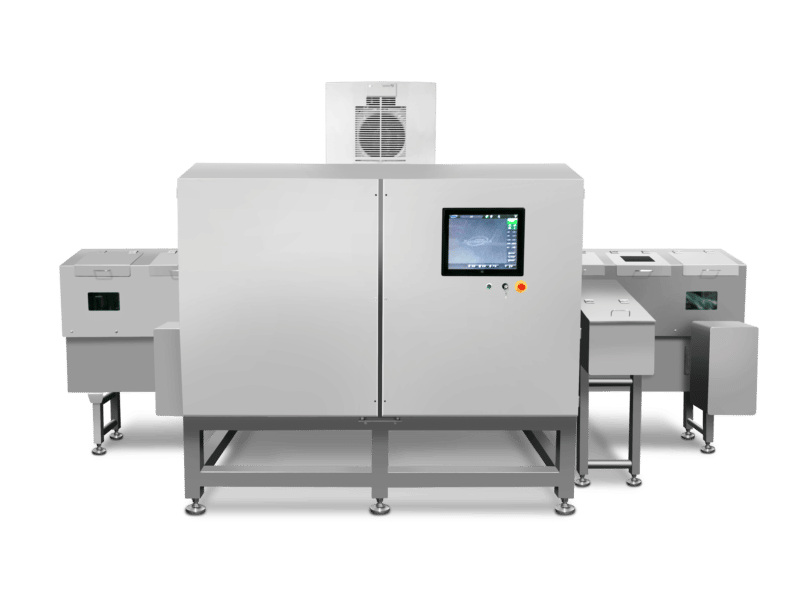

X-Ray Machine & Metal Detector

To further guarantee safety and accuracy for packaged goods, many of our clients also use other types of automated inspection equipment such as X-ray machines and metal detectors.

X-ray machines use low-level radiation technology to quickly scan packages for foreign objects such as glass shards or screws within packages which may have been inadvertently included during the production process. Both X-rays and metal detectors are invaluable pieces of equipment for food manufacturing companies as they can help protect against contamination and reduce the risk of costly product recalls or repackaging attempts after the fact.

Why BPI?

An automated checkweigher is one of many inspection solutions offered by BPI Equipment that should be incorporated into any food manufacturer’s packaging process in order to ensure accurate labeling, product safety compliance standards and improved quality assurance practices. Automated checkweighers allow businesses to guarantee precision in meeting weight specifications while providing faster results than manual methods — allowing them to remain competitive in today’s market while maintaining top-notch levels of consumer satisfaction.

Furthermore, using complementary X-ray machines and metal detectors alongside an automated checkweigher will help businesses identify potential hazards before they reach customers and offer additional peace of mind knowing their goods are safe from contamination throughout the entire supply chain process. BPI offers varying sizes and models to suit your operational scale and needs.

We’re your single source for automated packaging solutions. We offer a wide range of machines and tools to suit most packaging scenarios, so you can rest assured your food products are safe and compliant with all regulations. Contact us today to learn more about how we can help!